16 September 2020 //

Our NewslettersOur Events and Newsletters

DTM Packaging PUREFIL 2000 In-Line Walking Beam Flow Meter Filler

- Simple to operate, clean hygienic machine design, sanitary design product path ¨ Volume or weight filling with highly precise product dosing utilizing Mag or Mass flow meters

- Flush in Place system included with each machine

- Bottom-Up fill capability for foamy or high viscosity products

- Quick to change over, highly flexible for a wide range of products and container sizes

- Continuous motion servo driven system with speeds up to 300 BPM Available as a standalone filler or as part of a complete DTM designed bottling line.

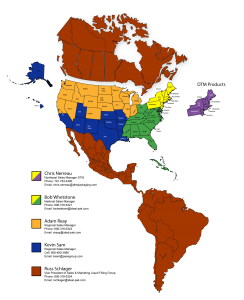

Contact your regional DTM sales manager for more information on this filling machine or DTM’s complete bottling line solution.

Purefil 2000 Walking Beam Filler for Beverage Products from DTM Packaging on Vimeo.

For Immediate Delivery

SINGLE HEAD DTM PUREFIL BENCH TOP GEAR PUMP FILLER

Small benchtop gear pump filling machine. Perfect for filling any personal care, hand sanitizer or any product requiring sanitary machine design. A wide variety of nozzle configurations and diameters to suit your application. Height adjustment accepts a wide range of containers. and will work with plastic or glass containers. No change parts needed for various types of containers.

- Two filling options selected from control panel (Time Fill or Fill by Pulse Count)

- Typical filling accuracy is +/- .5% at 1 sigma

- Fill nozzle is stationary laminar flow design – no stroking necessary

- HMI panel product volume control

- HMI panel product fill speed and variable fill speed control.

- Sensor for bottle presence control

- Adjustable platform guides for positive bottle positioning

- 304 Stainless steel heavy duty stainless steel welded frame.

- All contact parts are stainless steel, sanitary, Teflon, Viton and hoses per your requirements.

Pump fill start button and E-stop button mounted on fill deck, Allen Bradley PanelView HMI mounted in remote cabinet. The gear pump is contained within a solid 316 type stainless steel seamless vault with Tri-clover clamp connections. Calibrated guide for fast height changeovers. Machine mounted on 4 adjustable feet. Allen Bradley CompactLogix PLC for all machine logic functions. Special seals or hoses by order.

For information on this no leadtime machine, contact DTM’s Chris Nerreau at 781-783-4380.