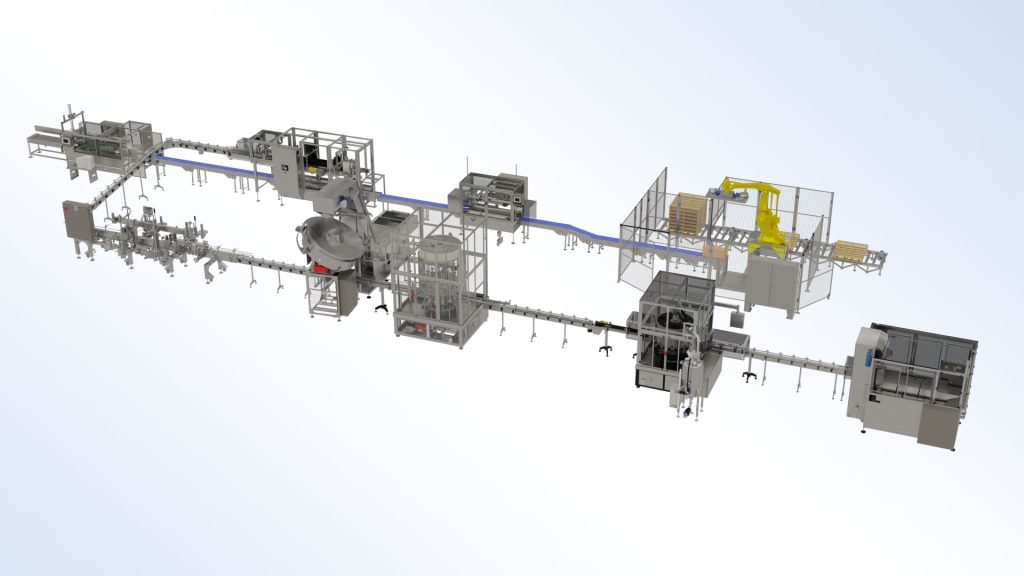

Complete System Integration

Packaging line integration involves designing, connecting, programming, and assembling a product line. This process lets you incorporate virtually any packaging machine you need to create a system for your unique products.

With systems integration from DTM Packaging, you can integrate new machines into your current packaging solution to create a fluent line. We know how to lay out, integrate, and set up your processes to meet your performance, accuracy, and speed requirements.