New Machines

New Machines

Explore our Packaging Machines and Solutions. For more information, contact us today!

Labelers

At DTM Packaging, we are proud to partner with Nita Labelers, a leader in innovative labeling technology. This partnership underscores our commitment to providing the highest quality packaging solutions through advanced technology to our customers.

Nita is known in the industry for their high-tech, user-friendly labeling machines. Their machines boast a host of features designed to minimize downtime and enhance operational efficiency. These include 100% license-free, non-proprietary electronics and software that are easy to maintain and readily available.

The versatility of Nita’s machines allows them to handle a wide range of labeling tasks such as applying front, back, wrap, and multi-panel labels on various materials including glass, plastic, and metal.

Our collaboration with Nita Labelers enables DTM Packaging to offer reliable, efficient, and cutting-edge labeling solutions to our clients. By integrating Nita’s innovative technologies into our services, we enhance our ability to meet diverse client needs with machines that are not just tools, but integral parts of an intelligent, streamlined packaging process.

Capping Machines

Cappers, Feeders, and Elevators for Efficient Packaging Solutions

At DTM Packaging, we offer advanced capping, feeding, and elevating solutions to streamline your packaging process. Our centrifugal cap feeder is specifically designed for exceptional flexibility, capable of sorting and feeding a wide range of cap shapes and sizes, including irregular shapes. This gentle control in handling is ideally suited for managing delicate finishes, ensuring product integrity.

With quick-change interchangeable center sections, our feeder can be changed over in a matter of minutes, significantly reducing downtime and enhancing operational efficiency. The cap feeder plays a critical role in the efficiency of your packaging line, providing a reliable supply of caps to the capping machine.

Our state-of-the-art cappers are engineered for precision and reliability, ensuring secure and consistent sealing of containers. They are compatible with a variety of cap types and container sizes, making them versatile for different production requirements. These cappers integrate seamlessly with our feeders and elevators, creating a cohesive system that optimizes the packaging process.

Elevators in our system are designed to transport caps efficiently to the feeder, maintaining a steady supply and reducing manual intervention. This automated solution not only enhances productivity but also ensures a smooth and continuous operation.

Learn more about our liquid filling machines.

Scroll down for more details on the variety of capper machines available

Bottle Pucking and Depucking Machines

A bottle pucking and depucking machine is a critical component in the packaging process, designed to efficiently handle and transport bottles through various stages of production by placing them into pucks for stability and later removing them for further processing or packaging. DTM’s bottle pucking and depucking machines stand out in the industry due to their superior stainless steel construction, rapid adjustability for different container sizes without the need for change parts, and the integration of advanced Allen Bradley electrics for reliable performance. Our machines are engineered with precision, featuring dual driven belts and back-up photo-eye sensors to ensure smooth, accurate, and safe operations.

With optional features like discharge chutes and puck return conveyors, DTM machines are tailored to meet the high standards and demanding requirements, ensuring enhanced efficiency, reduced downtime, and unmatched reliability in their packaging lines.

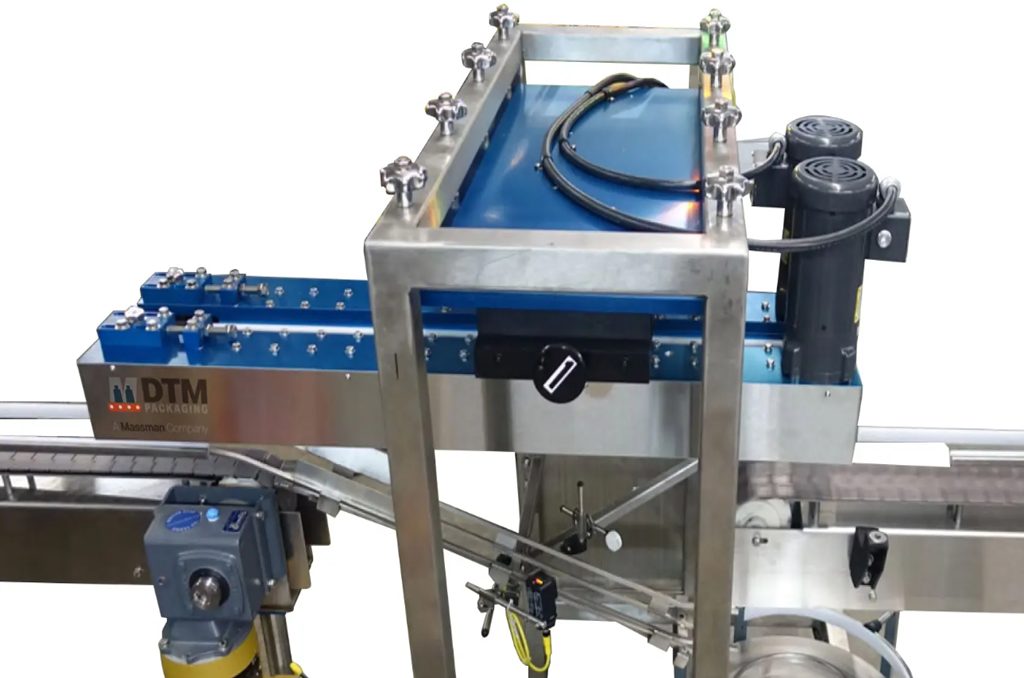

Accumulation Tables

Maximize your production efficiency with our robust and versatile Accumulation Tables, designed for seamless integration and superior performance.

Manufactured from 1/8” thick 304 stainless steel, these tables boast unparalleled strength and longevity, making them a reliable addition to any production line. The main structure, constructed from 2-inch stainless steel square tubing, ensures robust support and stability. The stainless steel disc is securely backed by a ½ inch aluminum plate, providing additional reinforcement. Encased in sleek stainless steel covers on all four sides, our accumulation tables are designed for both functionality and aesthetic appeal, blending seamlessly into any industrial environment.

Powered by a reliable DC gear motor, our Accumulation Tables offer variable speed control through an easy-to-use potentiometer, allowing for precise adjustments to suit your operational needs. Capable of handling up to 150 containers per minute, these tables significantly enhance productivity while minimizing downtime. Experience the perfect combination of cutting-edge engineering and user-friendly design with our Accumulation Tables. Scroll down to explore more details and access our comprehensive PDF guide to discover how our advanced solutions can elevate your production capabilities.

Learn more about our liquid filling machines.

Scroll down for more details & to view our PDF.

Conveyors for Bottles and Cases

At DTM Packaging, we specialize in providing high-quality conveyors designed specifically for bottles and cases. Our conveyors are built with rugged construction and a modular design, ensuring they meet the unique demands of your packaging line. The use of stainless steel construction guarantees durability, hygiene, and ease of maintenance.

Our conveyors are engineered to provide optimal performance, tailored to the specific needs of your production process. Whether you’re setting up a new line or upgrading an existing one, DTM Packaging delivers solutions that enhance efficiency and reliability.

Key Benefits of DTM Conveyors:

- Durable Construction: Withstands high-volume production.

- Modular Design: Customizable to your application.

- Hygienic Stainless Steel: Easy to clean and maintain.

Trust DTM Packaging to deliver the conveyor solutions that drive your success.