The DTM Sanitary Upgrade Package Provides for the following:

Product contact for all internal surfaces is designed to minimize the environment for microbial growth. We focus on minimizing nooks and crannies and internal surface finish to minimize micro-organism adaptation and growth.

Our system is easily cleanable, i.e. all intended surfaces have contact with the cleaning/sanitizing agent and the cleaning/sanitizing procedure is repeatable, and easily accomplished.

Given the above, we have established the following sanitary design features which are applied.

1. All piping and components are of a sanitary design/configuration and constructed with product contact surface of an FDA-approved material/finish. Generally 316 SS with a #4 finish.

2. All piping systems are passivated after construction completion with appropriate chemicals/procedures.

3. Our system is fully drainable without disassembly.

4. Piping is sloped 1/16″ per foot to a low point drain.

5. Materials for gaskets are customer specified.

6. System is designed to obtain 3-5 ft/sec water velocity required for washouts to adequately clean the system. For hard-to-clean products we use a high pressure, high volume washout.

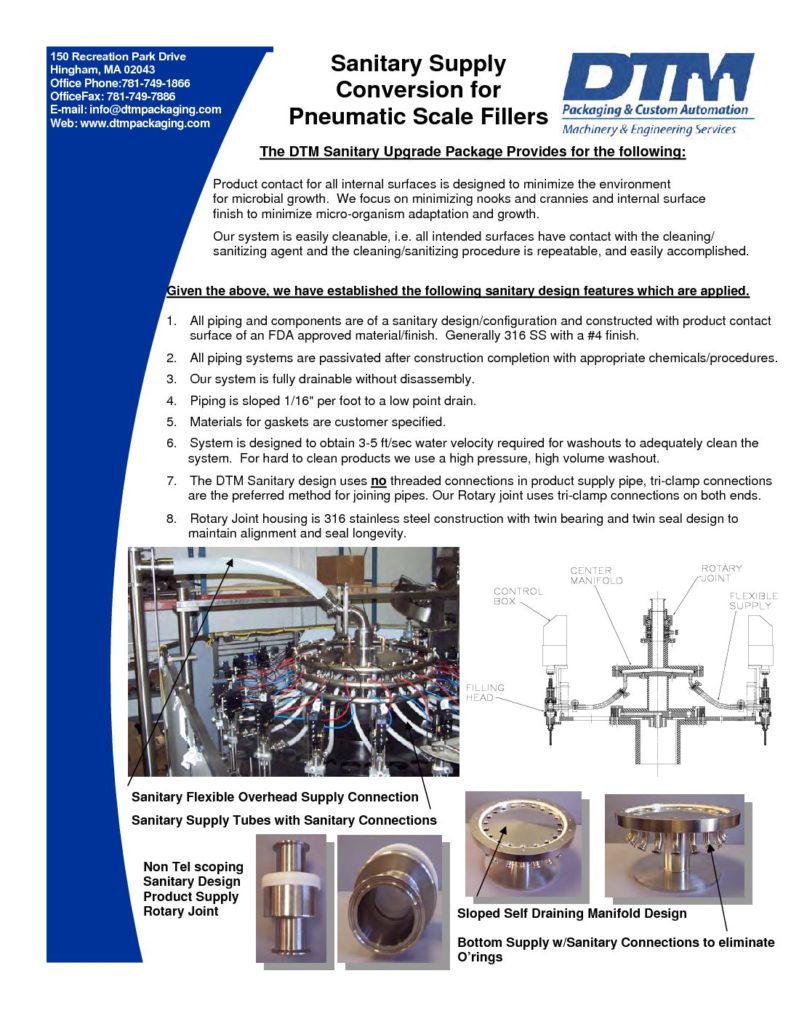

7. The DTM Sanitary design uses no threaded connections in product supply pipe, tri-clamp connections are the preferred method for joining pipes. Our Rotary joint uses tri-clamp connections on both ends.

8. Rotary Joint housing is 316 stainless steel construction with twin bearing and twin seal design to maintain alignment and seal longevity.