Machinery for Household Products

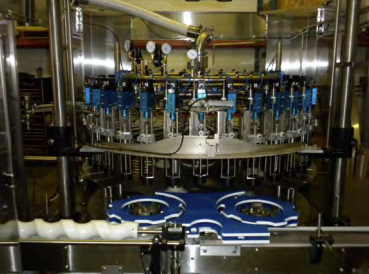

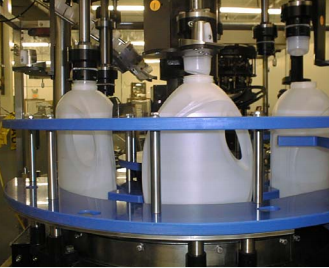

Filler Systems

Simple & Accurate Filling of your Product… Every time!

DTM Packaging’s Purefil family of In-line Flow Meter Fillers, like top-tier bottle fillers and liquid filling machines, combine top-tier design and innovative technology, solidifying its status as a best-in-class liquid filling solution. Available as an intermittent (Purefil 1500) or Continuous motion machine (Purefil 2000/2500) to fit your speed requirements.

- The filling equipment options include Mass flow meters, Magnetic flow meters, pressure overflow, time pressure, piston, or gear pump configurations

- Sanitary design of the entire product path within the filler, eliminating all points subject to potential contamination

- Average fill volume accuracy to +/- 0.25% standard deviation

- Indexing bottle control with adjustable entry and exit gating

- Servo & tool less changeover for fast product size changes

- No container, no fill safety and container neck guide control

- Flush in place tray for quick FIP process

- Safety interlocked Lexan guards

Scroll down for more details & to view our PDF.

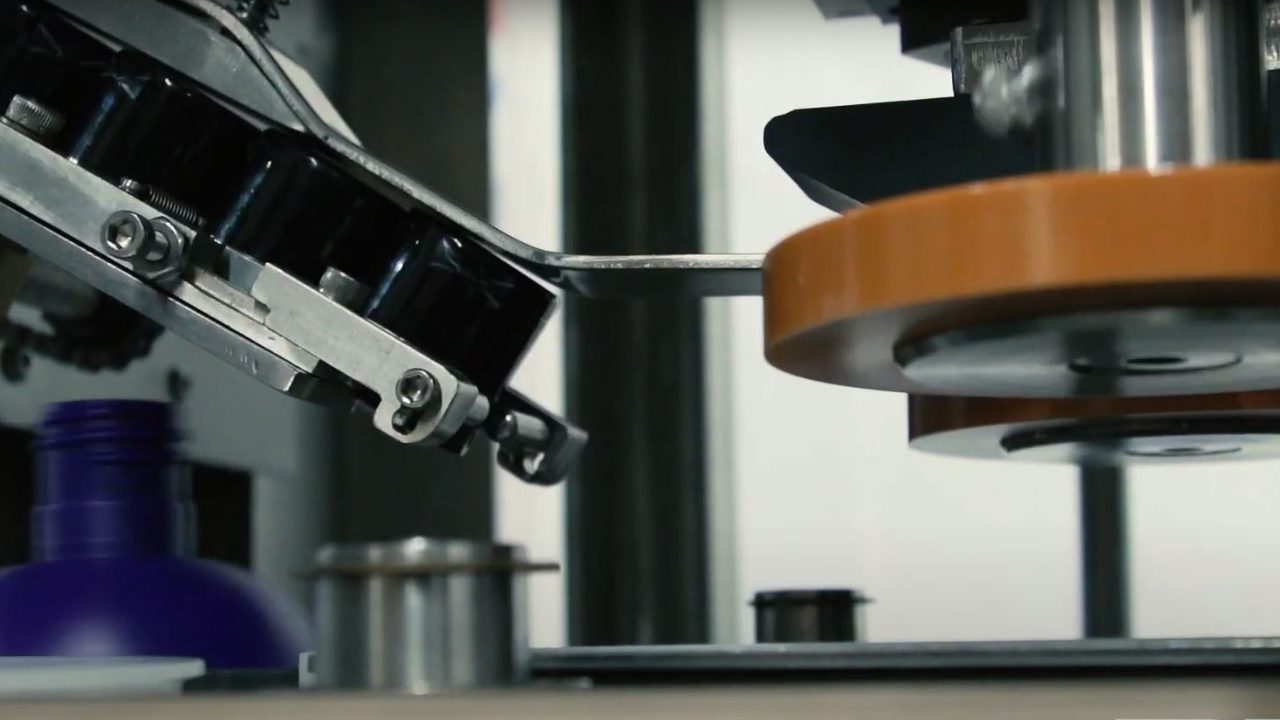

Capping Machines

Capping Systems, Feeders, and Elevators for Efficient Packaging Solutions

At DTM Packaging, we offer advanced capping, feeding, and elevating solutions to streamline your packaging process. Our centrifugal cap feeder is specifically designed for exceptional flexibility, capable of sorting and feeding a wide range of cap shapes and sizes, including irregular shapes. This gentle control in handling is ideally suited for managing delicate finishes, ensuring product integrity.

With quick-change interchangeable center sections, our feeder can be changed over in a matter of minutes, significantly reducing downtime and enhancing operational efficiency. The cap feeder plays a critical role in the efficiency of your packaging line, providing a reliable supply of caps to the capping machine.

Our state-of-the-art cappers are engineered for precision and reliability, ensuring secure and consistent sealing of containers. They are compatible with a variety of cap types and container sizes, making them versatile for different production requirements. These cappers integrate seamlessly with our feeders and elevators, creating a cohesive system that optimizes the packaging process.

Elevators in our system are designed to transport caps efficiently to the feeder, maintaining a steady supply and reducing manual intervention. This automated solution not only enhances productivity but also ensures a smooth and continuous operation.

Learn more about our liquid filling machines.

Scroll down for more details on the variety of capper machines available

Remanufactured Labeling Machine

Scroll down for more details & to view our PDF.

- 546-Mateer Burt In-Line Labeler

- 968 DTM Repak Wrap Labeler with Domino Coder

Remanufactured Heat Tunnel

Scroll down for more details & to view our PDF.

- 908-OAL Heat Tunnel

- 909-OAL Heat Tunnel

Monoblock Filler

Scroll down for more details & to view our PDF.

- 944-Monoblock Filler-Plugger-Capper

- 953-Pneumatic Scale (PSC) 36 Head Series 1350 Monoblock Filler

Remanufactured Bottle and Cap Elevators

Scroll down for more details & to view our PDF.

- 619-Cap Elevator

- 620-Cap Elevator

- 637-PSC Elevator

- 689-Kap L Elevator

- 745-Hoppmann Cap Elevator

- 750-Alpha Cap Elevator

- 751-DYCO Bottle Elevator

- 768-PSC Cap Elevator

- 830-Mengibar Cap Elevator

- 831-Mengibar Cap Elevator

- 904-Zalkin Cap Elevator

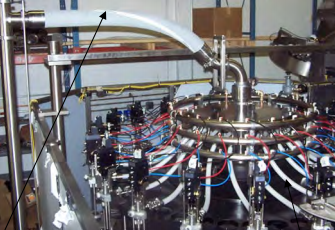

Inline and Rotary Fillers

Scroll down for more details & to view our PDF.

- 552-Pneumatic Scale (PSC) 16 Head Overflow Filler

- 638-Pneumatic Scale (PSC) 40 Head Pneumaflow Filler

- 660-Pneumatic Scale (PSC) 20 Head Series 900 Pneumaflow Filler

- 691-Pneumatic Scale (PSC) 40 Head Overflow Filler

- 836-Pneumatic Scale (PSC) 40 Head Pneumaflow Filler

- 864-Simplex Single Head Filler

- 867-Available (PSC) 32 Head Pneumaflow Filler

- 869-Pneumatic Scale (PSC) 32 Head C-Frame Filler

- 924-Pneumatic Scale (PSC) 20 Head B Frame Filler

- 927-Pneumatic Scale (PSC) 20 Head B Frame Filler

Remanufactured Transfer Belt System

Scroll down for more details & to view our PDF.

Remanufactured Tote Dump System

Scroll down for more details & to view our PDF.

- 920-Tote Dump System

- 920A-Tote Dump System

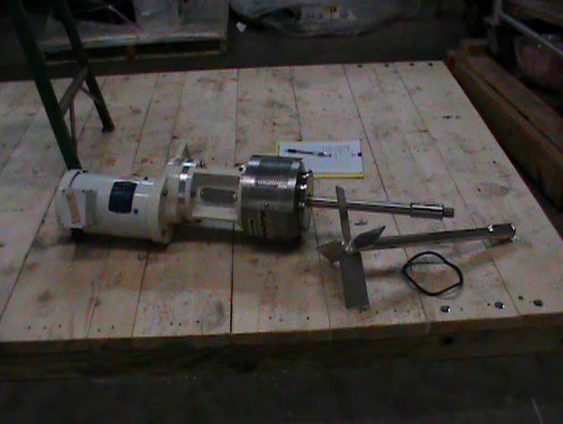

Remanufactured Tanks and Kettles

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Bottle and Table Unscrambler

Scroll down for more details & to view our PDF.

- 963 DTM Bottle Unscrambler

- 969 DTM Unscrambling Table

Remanufactured Neck Banders

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Miscellaneous Remanufactured Machinery

Inquire with our Sales department. Contact Us.

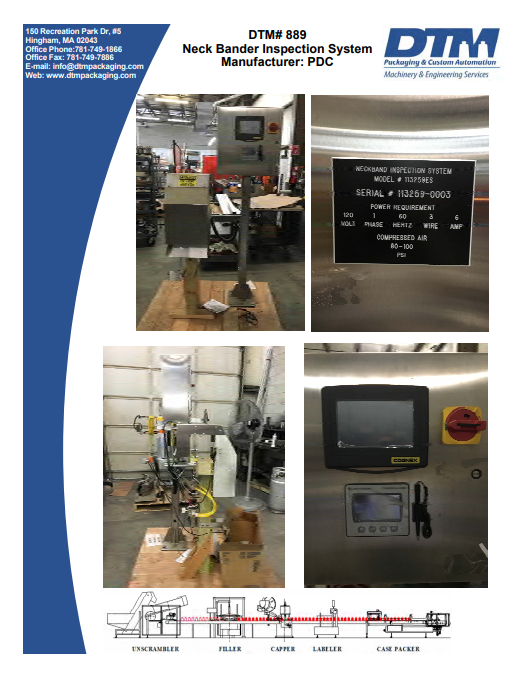

Remanufactured Neck Bander Inspection System

Scroll down for more details & to view our PDF.

Remanufactured Dust Collectors

Scroll down for more details & to view our PDF.

Remanufactured Dose Cup Placers

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Conveyer Machinery

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Coding Equipment

*945-Open Date Coder – View Flyer Below*

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Cleaning Equipment

Scroll down for more details & to view our PDF.

- 883-PSC 18 Head Ultra Cleaner

Check Weigher Machinery

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Case Packers

Inquire with our Sales department. Contact Us.

Remanufactured Case Erector

Inquire with our Sales department. Contact Us.

Remanufactured Cappers and Pluggers

Scroll down for more details & to view our PDF.

- 954-Pneumatic Scale

Inline and Rotary Remanufactured Cappers

Scroll down for more details & to view our PDF.

- 514-Pneumatic Scale (PSC) 6 Head Tub Basin Capper

- 529-Kalish Single Head Capper

- 556-Pneumatic Scale (PSC) 6 Head Capper with 3A Feeder

- 593-Consolidated J815 Capper

- 617-Pneumatic Scale (PSC) 12 Head Capper

- 630-Pneumatic Scale (PSC) 8 Head Capper

- 639-Pneumatic Scale (PSC) 8 Head Tub Basin Capper

- 640-Pneumatic Scale (PSC) 6 Head Capper

- 697-Pneumatic Scale (PSC) 8 Head Capper

- 716-Pneumatic Scale (PSC) 8 Head Capper

- 766-Shibuya Pump Placer

- 766A-Shibuya Capper

- 796-Pneumatic Scale (PSC) 8 Head A Capper

- 799-Consolidated J-8 Rotary Capper

- 821-Pneumatic Scale (PSC) 8 Head B Capper

- 826 Mengibar 8 Head Snap Capper

- 853-Pneumatic Scale (PSC) 12 Head B-Frame Capper-22257

- 857-Pneumatic Scale (PSC) 8 Head A-Frame Capper

- 870-Pneumatic Scale (PSC) 8 Head B-Frame Capper

- 880-Consolidated D-6

- 884-Pneumatic Scale (PSC) 8 Head A-Frame Capper

- 899-Consolidated TG-10

- 922-Pneumatic Scale (PSC) 8 Head B-Frame Capper

- 923-Pneumatic Scale (PSC) 6 Head Capper

- 925-Pneumatic Scale (PSC) 8 Head Capper

- 930-Pneumatic Scale (PSC) 4 Head B-Frame Capper

- 936-Pneumatic Scale (PSC) 8 Head Capper

- 937-PMC 6 Head Pump Capper

- 938-PMC 6 Head Capper

- 942-Consolidated 8 Head Capper

- 955-Pneumatic Scale (PSC) 12 Head B-Frame Capper

Remanufactured Cap Feeder Machinery

Scroll down for more details & to view our PDF.

- 530-Vibratory Cap Feeder

- 535-PSC F136 Cap Feeder

- 565-Vibratory Feeder

- 582-PSC Horizontal Cap Feeder

- 597-Hoppman FR30

- 636-Horizontal Cap Feeder

- 643-Consolidated Horizontal Cap Feeder

- 654-Pocket Feeder

- 713-PSC 3A Cap Feeder

- 717-Hoppman FT30 Cap Feeder

- 739-PMC Cap Feeder

- 767-Pocket Style Cap Feeder

- 797-PSC Vibratory Cap Feeder

- 800-Consolidated Cap Feeder

- 816-Ronchi Pocket Style Cap Feeder

- 829-Mengibar Pocket Feeder

- 901-Anderson Cap Sorter

- 902-Zalkin Cap Sorter

- 913-PSC 3A Feeder

- 919-Cap Feeder MFG T-Group

- 929-PSC 3A Feeder

- 939-3A Feeder

- 957-42 Inch Pocket Feeder

Remanufactured Bundlers and Wrappers

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

733-NEM Remanufactured Bottle Unscrambler

Scroll down for more details & to view our PDF.

- 733-NEM Bottle Unscrambler

- 772-Omega Bottle Cleaner

Bottle Pucking and Depucking Machines

A bottle pucking and depucking machine is a critical component in the packaging process, designed to efficiently handle and transport bottles through various stages of production by placing them into pucks for stability and later removing them for further processing or packaging. DTM’s bottle pucking and depucking machines stand out in the industry due to their superior stainless steel construction, rapid adjustability for different container sizes without the need for change parts, and the integration of advanced Allen Bradley electrics for reliable performance. Our machines are engineered with precision, featuring dual driven belts and back-up photo-eye sensors to ensure smooth, accurate, and safe operations.

With optional features like discharge chutes and puck return conveyors, DTM machines are tailored to meet the high standards and demanding requirements, ensuring enhanced efficiency, reduced downtime, and unmatched reliability in their packaging lines.

Remanufactured Bottle Orienter

Scroll down for more details & to view our PDF.

Remanufactured Ball Placer

Our goal at DTM Packaging is to provide you with the best automated equipment solutions at the lowest possible cost.

Reach out to our team for a customized line integration or equipment quote today!

Remanufactured Resina Belt Conversions

Top and Bottom Belts, 1″ Wide with a Linatex, 3/8″ Thick Material

Complete Rebuilds Including:

- New Safety Guarding Package

Scroll down for more details & to view our PDF.

Our Remanufactured Equipment

Scroll down for more details & to view our PDF.

Remanufactured PSC Capper

Scroll down for more details & to view our PDF.

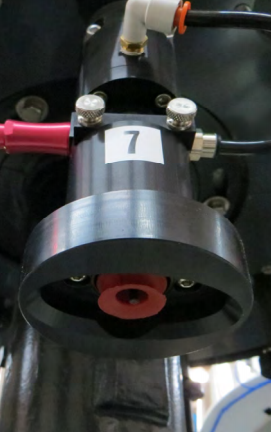

Remanufactured PSC 32 Rotary Level Sensing Filter

Scroll down for more details & to view our PDF.

Remanufactured Plug-Spout Inserter

Scroll down for more details & to view our PDF.

Remanufactured 20 Head Filler with 6 Head Capper

Scroll down for more details & to view our PDF.

Remanufactured PSC 16-32 Head Filler with 6-12 Head Capper

Scroll down for more details & to view our PDF.

Rubber Parts for Replacement

We carry parts in a wide range of sizes and materials, and we can create custom replacement parts for unique applications. Our rubber components include:

- Chuck inserts for pneumatic scale and consolidated cappers.

- Capper drive wheels.

- Pace and New England unscrambler pads.

- Resina capper gripper blocks.

- Rubber belts for pneumatic scale bottle cleaners.

- Replacement belts for machines from New England, Kaps-All, and other manufacturers.

- Nozzle seal washers.

Scroll down for more details & to view our PDF.

Sanitary Supply System for PSC Fillers

We offer a sanitary supply system upgrade for pneumatic scale capper (PSC) fillers. This system reduces the environment for potential microbial adaptation and growth by decreasing tight corners and internal surface finish. The system is easy to clean by contacting the surfaces with a sanitizing agent.

Some of the upgrades included are:

- Piping and components with a sanitary configuration and FDA-approved material.

- Passivated piping systems from chemical procedures.

- 1/16-inch slope per foot to a drain.

Upgrades for PSC Control Boxes

DTM Packaging offers replacement and changing parts for PSC control boxes, including Phase I, Phase II, Phase III, and ALC boxes. We can also upgrade the PSC control box sensing head to improve accuracy and access single-control adjustment. You can replace the spring lever system with a ball tip on the filler.

Scroll down for more details & to view our PDF.

- Control Box Upgrades

- Pneumatic Scale Control Box Parts

Replacement Parts for PSC Cleaners/Fillers/Cappers

Order replacement components for your PSC capper, filler, and cleaner. These parts feature our latest design, making the cap grippable from the side. This setup is advantageous for multiple cap sizes with quick changeovers.

Scroll down for more details & to view our PDF.

- Chuck Gripper System for Pneumatic Scale Cappers

- Pneumatic Scale Capping Parts

PSC Magnetic Torque System

You can update your PSC with our magnetic torque system featuring a hysteresis design to extend the life of the capping heads. The capping chuck floats to reduce ratcheting and the likelihood of cross-threading.

Scroll down for more details & to view our PDF.

Custom and Standard Filling Nozzles

We offer precision-engineered filling nozzles, including components and entire assemblies, manufactured from materials such as nylon, Delrin, 316 stainless steel, and polyvinyl chloride (PVC). These parts are designed for a variety of machines, including:

- Level-sensing fillers.

- Pressure fillers.

- Gravity fillers.

- Vacuum fillers.

Scroll down for more details & to view our PDF.

DTM Change Parts

Our change parts allow you to switch over to other bottle sizes and run multiple sizes of containers on one production line. Some of these components include:

- Quick change bottle centering guides.

- Stars and center guides.

- Quick change guide rails.

- Helices.

- Quick change core components.

- Color-coded parts.

- Quick change helix mounting.

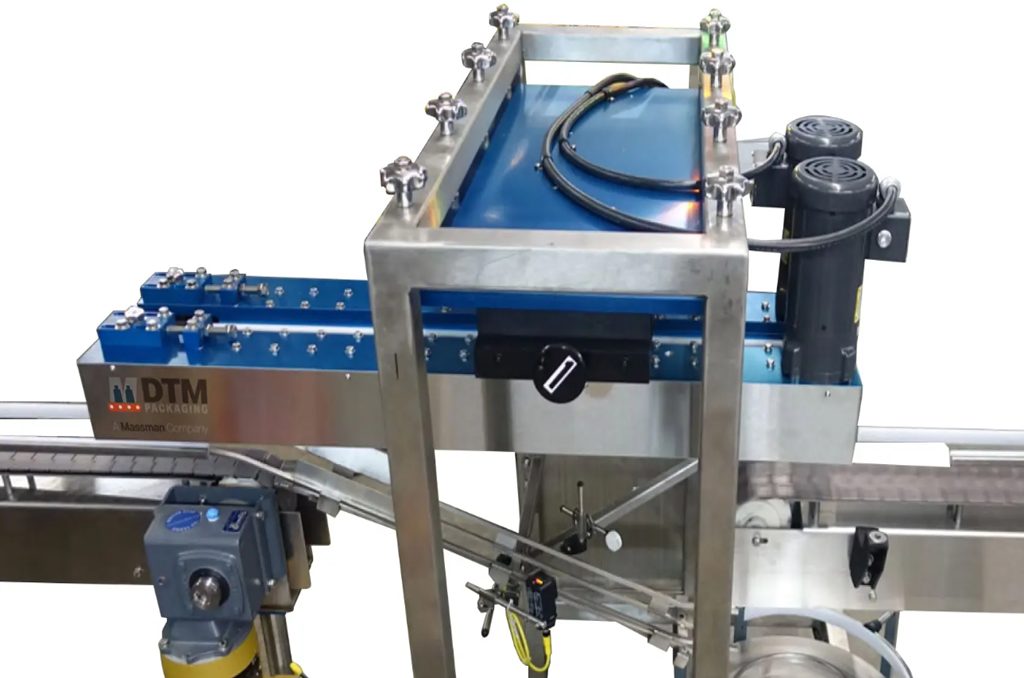

Accumulation Tables

Maximize your production efficiency with our robust and versatile Accumulation Tables, designed for seamless integration and superior performance.

Manufactured from 1/8” thick 304 stainless steel, these tables boast unparalleled strength and longevity, making them a reliable addition to any production line. The main structure, constructed from 2-inch stainless steel square tubing, ensures robust support and stability. The stainless steel disc is securely backed by a ½ inch aluminum plate, providing additional reinforcement. Encased in sleek stainless steel covers on all four sides, our accumulation tables are designed for both functionality and aesthetic appeal, blending seamlessly into any industrial environment.

Powered by a reliable DC gear motor, our Accumulation Tables offer variable speed control through an easy-to-use potentiometer, allowing for precise adjustments to suit your operational needs. Capable of handling up to 150 containers per minute, these tables significantly enhance productivity while minimizing downtime. Experience the perfect combination of cutting-edge engineering and user-friendly design with our Accumulation Tables. Scroll down to explore more details and access our comprehensive PDF guide to discover how our advanced solutions can elevate your production capabilities.

Learn more about our liquid filling machines.

Scroll down for more details & to view our PDF.

Conveyors for Bottles and Cases

At DTM Packaging, we specialize in providing high-quality conveyors designed specifically for bottles and cases. Our conveyors are built with rugged construction and a modular design, ensuring they meet the unique demands of your packaging line. The use of stainless steel construction guarantees durability, hygiene, and ease of maintenance.

Our conveyors are engineered to provide optimal performance, tailored to the specific needs of your production process. Whether you’re setting up a new line or upgrading an existing one, DTM Packaging delivers solutions that enhance efficiency and reliability.

Key Benefits of DTM Conveyors:

- Durable Construction: Withstands high-volume production.

- Modular Design: Customizable to your application.

- Hygienic Stainless Steel: Easy to clean and maintain.

Trust DTM Packaging to deliver the conveyor solutions that drive your success.

Remanufactured Cleaner/Filler/Capper

Scroll down for more details & to view our PDF.

Consulting and Engineering Services

Offering Customized Packaging Solutions

- Face-to-face meetings to get a thorough understanding of your production line requirements and challenges.

- Time and cost-saving approaches to accommodate multiple package sizes and shapes.

- Equipment recommendations that are best for your specific application.

- Project management from quotation to installation of the packaging line at your facility.

- An engineering department of machinery and line integration experts ensuring your line integration project will run smoothly and efficiently.

- Assistance with making budget decisions and project cost projections.

- Packaging equipment installation, start-up and training to assure project time schedules are maintained.

- Customized PLC programming and support for the best in operator interfacing.

- Upgrades to existing bottling lines to increase cost and productivity efficiency through machinery reconditioning or complete rebuilding.

Scroll down for more details & to view our PDF.

Custom Automation Division

Our Custom Automation Division has highly skilled mechanical and electrical engineers who have a wide range of experience in specialty machines and control systems. They will lead you, the Customer, from concept, through all the engineering, build and debug stages to make your automation program a complete and successful turnkey operation.

The difficult and high-risk areas of the design are modeled or prototyped to assure success and steady progress in completing the task. Once a concept is clarified, an overall design layout is created. After design reviews, detailed drawings are produced for parts fabrication.

When assembly is complete, all aspects of machine operation and safety are tested and demonstrated for the customer before any equipment leaves our shop.

In addition to service, we also offer complete electrical and mechanical documentation including an operation and maintenance manual along with a

recommended spare parts list.

Scroll down for more details & to view our PDF.

Custom Automated Packaging Machines | DTM Packaging

DTM Packaging has been an industry leader in creating custom automated packaging machinery tailored to the unique needs of our customer’s packaging process. Our solutions are designed to enhance efficiency, reliability, and productivity in your production line. With a focus on rugged construction, advanced technology, and seamless integration, our custom machinery ensures optimal performance and long-lasting durability.

Why Choose DTM Packaging for Custom Machinery?

- Tailored Solutions: Each machine is engineered to meet your specific bottling requirements.

- Advanced Technology: Incorporates the latest in automation and control systems.

- Rugged Construction: Built to withstand the demands of high-volume production environments.

- Seamless Integration: Designed to work seamlessly with your existing equipment

As we lean into our specialty of designing and manufacturing high-speed industry leading liquid filling machines with our Purfill line of machinery, our expertise in liquid filling applications ensures you get the best solutions. Our team is available to consult on your specific packaging needs and guide you to the optimal packaging solution for your business.